HOSE MANUFACTURE CONTAMINENTS

Hydraulic systems require clean, contaminant-free oil for

efficient and reliable operation. Contaminants can come

from a number of sources and find their way into the system

which is why filters play an important role.

The pressurised oil can quickly carry the contaminants

through the entire system causing premature failure of

components, internal leakage and power losses.

Many contaminants are produced at hose manufacture stage.

Whether they be for new systems or replacement in old systems –

all hydraulic lines should be free of contaminants. Filters

can quickly clog up and depending on where the contaminants

entered the system the damage could be already done before passing

through the filters.

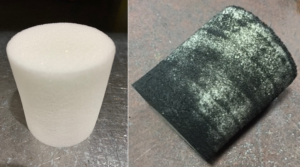

Cut-off saws and drop saws can produce large amounts of

rubber and metal particles. In the below image, on the left is

a clean projectile, on the right, is a picture of a projectile that

was fired down a 2”multi-spiral hose after being cut by a

drop saw.

This is why, here at Gerrard Hydraulics, all hoses

manufactured are projectile cleaned during assembly then

plugged or capped off at both ends thus ensuring one less

source of potential damage to your system.

If you manufacture your own hoses and have an air

the compressor we highly recommend getting a projectile gun

and projectiles for the various hose sizes you work with.

Get in touch with us today for pricing or more information.